Reducing our footprint

In today’s society, the realisation that we need to treat our raw materials and energy with care has become mainstream. Saving on these matters also brings about financial gains. The following principles apply.

Minimal use/maximum utilisation of products

“A lamp that isn’t lit consumes the least.” Analogous to these wise words, shared workstations are now replacing individual workstations for every employee. This development falls under the category of ‘the new way of working’.

We consider this principle as self-evident when designing offices. Our furniture offer excellent possibilities in this regard. A workstation barely used or not at all reduces the efficiency of space, materials and maintenance. We certainly want to (help) avoid this.

A long service life for minimum consumption

The next principle involves the service life of a workstation. High-quality material needs to be replaced less frequently, another way of optimising the use of raw materials and energy. It is safe to say that our furniture is rarely replaced as a result of wear. Rather, it may end up being replaced eventually because it no longer meets the needs of the day.

Efficient production

Another way of optimising raw materials and energy is to consume as little as possible when manufacturing products. In this regard, we are always on the ball. Our processes are becoming increasingly efficient and environmentally friendly, and our products are always designed and redesigned to take up ‘less’ raw materials and energy.

Energy consumption in the use phase

Our products typically require little energy for maintenance and use. This phase is therefore negligible.

End of life or even better: “a second life”

If our products end up being ‘discarded’ by the user, they are rarely so worn that nobody can give them a second (or third) life. First and foremost, thrift shops are the answer to give used office furniture a new purpose or they can be donated to charities.

When it’s really over

When the time has come to dismantle a piece of furniture, the components are easy to separate into main fractions such as steel, aluminium, wood and plastic. All our furniture is easy to dismantle with simple tools. We aim for 100% separability. Wherever this remains impossible at the moment, we are taking action to achieve it. Almost all of our plastic parts are already being marked with material identification. When this isn’t feasible in smaller parts due to small surfaces, we are working on it.

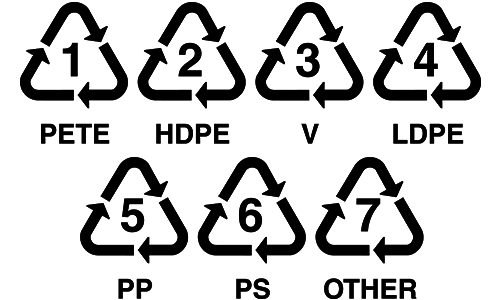

MATERIAL IDENTIFICATION

Separation of residual fractions: this is where the number or abbreviation comes in for recycling chains:

- PET = polyethene - terephthalate: soda and mineral water; detergents and liquid pharmaceutical products, blister packs and tubes.

- HDPE = high-density polyethene: jars/jerrycans, crates and bins, foil for waste bags.

- PVC = polyvinyl- chloride: blister packs for medication; foil for fresh produce, tube systems.

- LDPE = low-density polyethene: foil such as shrink sleeves, tubular foil, bags and cover sleeves for a variety of applications.

LLDPE = linear low density polyethene: very thin foils: stretch film or stretch foil for wrapping pallet loads. - PP = polypropylene: buckets, crates, boxes, bottle/flask caps, transparent packaging for flowers.

- PS = polystyrene: disposable tableware, trays and dishes for meat and vegetables; boxes for ice cream, for example.

- EPS = expanded polystyrene: buffer packaging for household appliances and electronics. PC = polycarbonate: multi-use milk bottles and certain (multi-use) containers for other liquids CDs / DVDs / etc.